Flyback transformers are crucial in power supply design, allowing for efficient energy storage and voltage conversion in various electronic devices. With applications in industries including telecommunications, consumer electronics, and automotive electronics, these transformers are essential for ensuring reliable and stable power delivery. Their compact size and high efficiency make flyback transformers a fundamental component in modern electronic systems.

The world of industry moves very fast and as such, it is crucial to have reliable and efficient equipment in order to maintain productivity and profitability. This is where the flyback transformer comes into play. This adaptable piece of equipment can be operated under severe conditions and heavy workloads, making it ideal for industrial purposes.

Integration of a flyback transformer into your machinery will ensure that the systems get quality power which is required if they are to achieve optimal efficiency. It not only enhances the performance of your devices but also prolongs their lifespan thus saving time and money spent on expensive repairs or replacements. Do not let unstable power sources hinder your business; acquire a flyback transformer for elevated industrial operations.

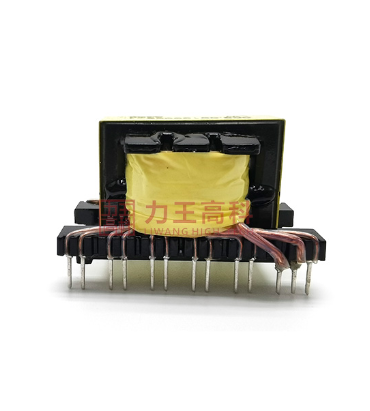

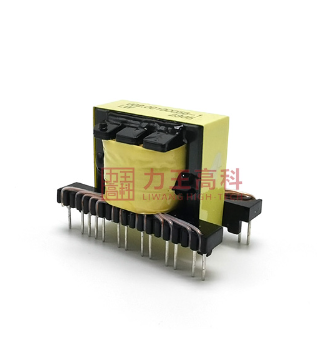

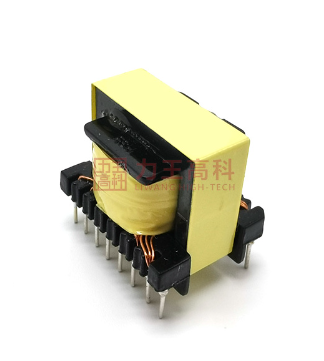

In the world of power electronics, the flyback transformer is a key element in energy conversion efficiency. It is capable of handling high voltages and currents thus making it an essential component in various applications including switching power supplies, inverters and SMPS (switch mode power supplies). It steps down or steps up voltages effectively making sure that your gadget gets exactly what it needs in terms of electricity thereby optimizing its performance and extending its life span.

The feature that makes the flyback transformer unique is its compact design which allows for easy portability in portable devices and appliances. Its rugged construction ensures durability as well as reliability even under extreme conditions. Whether you want to upgrade your home theater or make your industrial equipment more efficient, then the flyback transformer is the best solution to go for better power management.

In power management, one size does not fit all. This is why customized flyback transformers are increasingly being embraced by both professionals and enthusiasts. By tailoring the transformer design to your specific application needs, you can attain unrivalled precision as well as performance levels.

May it be for a groundbreaking research project or a customized audio amplifier to be built, having a customized flyback transformer guarantees that your system is performing at its best. By allowing voltage and current levels to be adjusted according to one’s own requirements specifically, there are no limitations in the areas of specialization. Buy yourself a custom made flyback transformer and make the difference that sets you apart from others in the same field.

As technology continues to evolve at an unprecedented pace, it's more important than ever to ensure that your electronics are equipped to handle the demands of tomorrow. That’s why investing in a flyback transformer is not just a smart decision – it is also forward-thinking.

With the application of a flyback transformer into your system, you will improve its today performance alone but also prepare it for future technology advancements. You can be confident that your electronics will cope with any emerging innovations. Don’t lag behind the digital age– secure your electronics by buying a flyback transformer today.

Guangdong Liwang High-tech Co, Ltd. was founded in October 2004 and is located in Huizhou, a national civilized city. Liwang is a national high-tech enterprise integrating R&D, production and sales. The company has obtained ISO9001, ISO14001,ISO18001, QC080000, IATF16949 quality system certification, products in line with RoHS, halogen-free, REACH requirements.

The company's business focuses on inductors and transformers, mainly used in magnetic components in the electronic industry such as new energy photovoltaic energy storage, OBC, mobile phone chargers, adapters, etc., and the end customers are Huawei,Sungrow,Goodwe,Sofar, BYD, Kstar, OPPO, Vivo, Mi, Honor, Amazon, LG, MOTO, Deye,etc...

The company, outstanding electronic materials supplier,has a number of intellectual property rights, including 1 corporate brand project, 4 registered trademarks, 159 patent information, 13 software copyrights2, enjoy a high reputation in the industry. Domestic and overseas, the company's products are also deeply trusted by customers.

Highly efficient and powerful, the Charger Transformer features a compact design for easy integration, durability for long-term reliability, advanced safety features, and compatibility with various electrical systems.

Our Ferrite Core Inductor stands out with high inductance, low core losses, and exceptional EMI suppression, ensuring efficient energy transfer and reliable performance across diverse applications.

With advanced core materials and winding techniques, our High Frequency Transformer delivers efficient and reliable power transfer, compact size, and high frequency operation for demanding applications.

Your inductors are excellent, with better prices for the same quality. We look forward to continuing our cooperation next time

Flyback transformers contribute to increasing energy efficiency by storing input power in a magnetic field and releasing it through controlled switching, minimizing power loss in power supply designs.

Yes, flyback transformers can be customized to meet specific voltage and power requirements for industrial equipment based on your unique specifications.

Our flyback transformers comply with industry-specific standards and certifications such as UL, CE, and RoHS, ensuring their suitability for various industrial applications.

The typical lead time for ordering flyback transformers in bulk quantities for manufacturing needs is [insert lead time based on company's policies.

The typical lifespan of a flyback transformer used in industrial electronic applications depends on various factors such as temperature, operating conditions, and quality of materials used. However, with proper care and maintenance, a flyback transformer can last for several years.